Meliomar Inc. is a tuna and seafood processing and export company based in Manila, Philippines. Meliomar focus on the development and trade of responsibly produced and high quality sustainable seafood, sourced from small-scale fisheries from areas throughout the Philippines.

Meliomar is a commercial partner of the Artsemar program for fisheries improvement run by Blueyou Consulting, based in Switzerland. By creating direct market access for seafood caught by smallholder fishers, the Artesmar initiative promotes the development of more sustainable business and fishing practices.

Blueyou leads and participates in Fishery Improvement Projects, one of which projects was to implement an Emydex electronic data capture production control system in the Meliomar operation to replace their existing manual system. They were also looking for a comprehensive real-time Traceability system to replace their manual paper-based system for traceability recording and reporting.

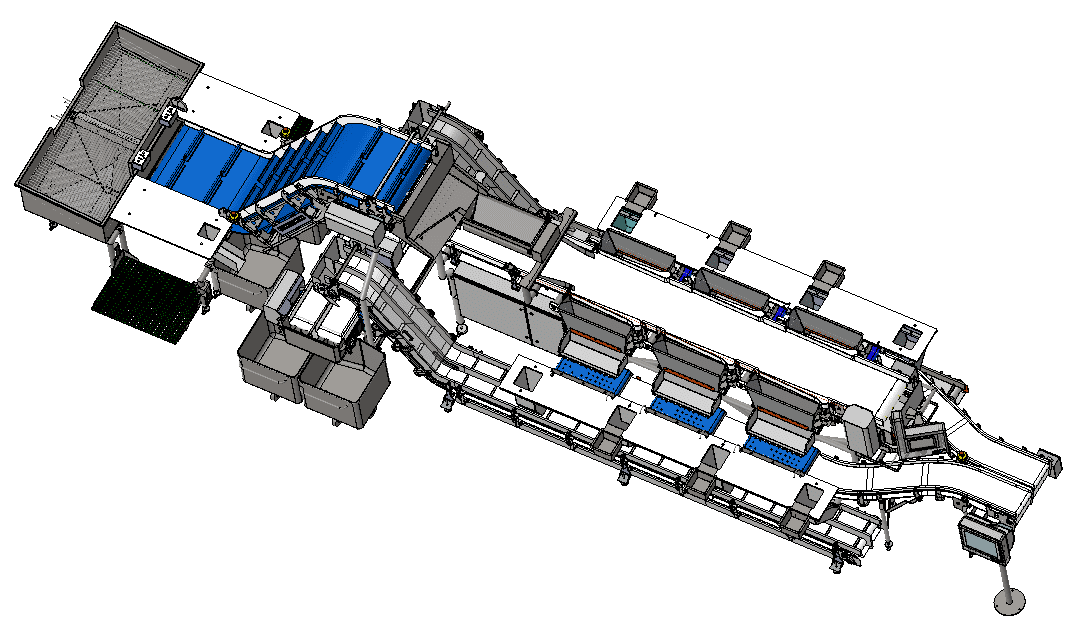

Door-to-door Factory Floor System

Emydex implemented their Intake, Packing & Processing, Order Management and Warehouse Management software modules to cover Meliomar’s factory floor processes, from factory door-to-door including Procurement, Reception, Manufacturing, Packing, Sales Order Picking and Dispatch. As part of the implementation Emydex also built a series interfaces to their back-office ERP system, Microsoft Dynamics NAV.

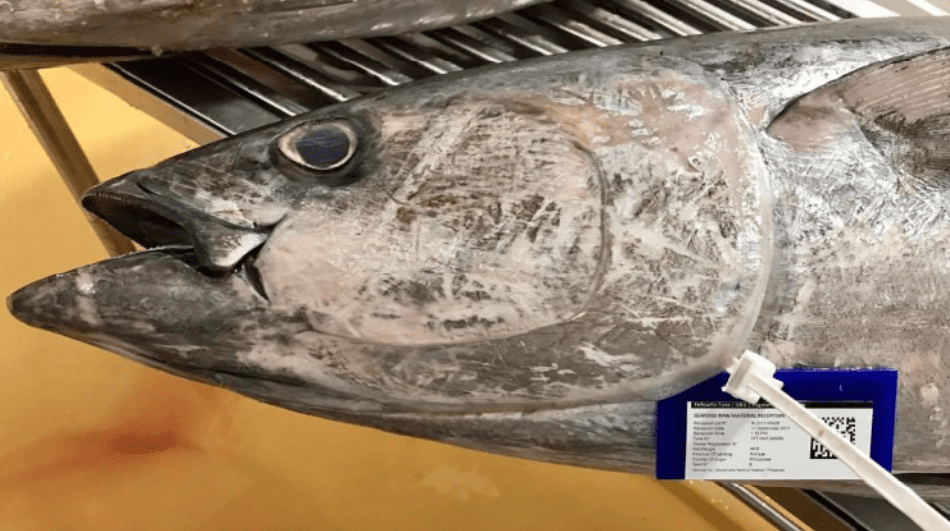

As Meliomar source fish from a multitude of suppliers and fishermen, Tuna ID tags are recorded as the fish are purchased. Each ID tag has a unique number made up of a location code and a consecutive number. Data capture and quality data is recorded at intake using a fixed position weighing station. Four labels are printed for each fish at intake, one for each loin, to ensure traceability is fully maintained throughout processing, using 2D Barcodes.

Meliomar’s business processes required Emydex to be more flexible in their approach to the system design, including the requirement to pack directly to Sales Orders pulled from NAV, as opposed to packing to stock.

Another requirement was the need to perform both Intake and Dispatch in off-line mode, as well as online (via wi-fi and network), due to poor internet connection in one of their factories. Meliomar needed functionality that allowed the creation of Purchase Orders and printing pallet labels on-site, and then load the POs onto a hand-held scanner.

The scanner and labels are later brought to a separate frozen storage facility, where they label pallets, enter the number of boxes on that pallet, and scan the pallet against a PO. When they get back to the main site, the data is then synced, and the data can be viewed on the system.

Predictive Re-Ordering

A key feature of this project was predictive re-ordering, which is based on average usage of a selected frozen product based on previous usage levels. Additional functionality allows them to optionally set a multiplier for a given week, in the event that they think they will be using more than the predicted amount for any given week. They can also set lead times for each product and receive warnings indicating that they will need to make a purchase order to maintain sufficient stock, or forecast when they will be out of stock, ensuring they have full visibility over stock levels at all times.

Production and Traceability Reporting System

Meliomar now have a comprehensive Production control & Traceability reporting system operating on the factory floor from door to door. By migrating from a manual system to an electronic data capture production reporting system and implementing an Emydex traceability system, this allows Meliomar to reliably trace all tuna products direct from their origin.

Commenting on the project, Christian Schmidradner, Meliomar General Manager said “Trust in the system is fast growing and the teams see how much less work is involved in processes (before handwritten and Excel inputted numbers in the thousands in forms, tedious hand-written reports to cross check for accounting and traceability purposes) and they have started to appreciate the system. We are very happy with the new system and I want to thank the Emydex team for their dedication and intensive work on customising and implementing our system over the last year”.

David McMahon, Emydex CEO added “the Meliomar system build was an interesting project in that the project was led for the customer by the BlueYou Consulting team in Switzerland, with the end-user and factory operations based in Manila, Philippines. Full credit to the combined project management and technical delivery teams for the successful configuration and implementation of a tailored Emydex factory floor solution for Meliomar, including integration to 3rd party industrial equipment and back-office systems, without ever having to visit the Philippines”.