Traceability Reporting Software

Traceability is one of the most important fundamental requirements for any food production facility. Being able to quickly and effortlessly trace product backwards or forwards whilst ensuring it is accurate is vital.

Traceability is inherited within each module of the Emydex platform and is designed to reduce the size of potential recalls and uses the Emydex reporting functions to provide instant traceability reports. Emydex system is able to provide various methods and levels of traceability depending on your factories processes.

Traceability Reporting

Benefits of our System

Traceability Reporting

System Features

One Step Back – One Step Forward

As a minimum requirement for traceability is to record one step back and one step forwards in the traceability chain. This could be recording from which abattoir or supplier an animal, carcass or primal was received from and when it was received.

Forwards Traceability

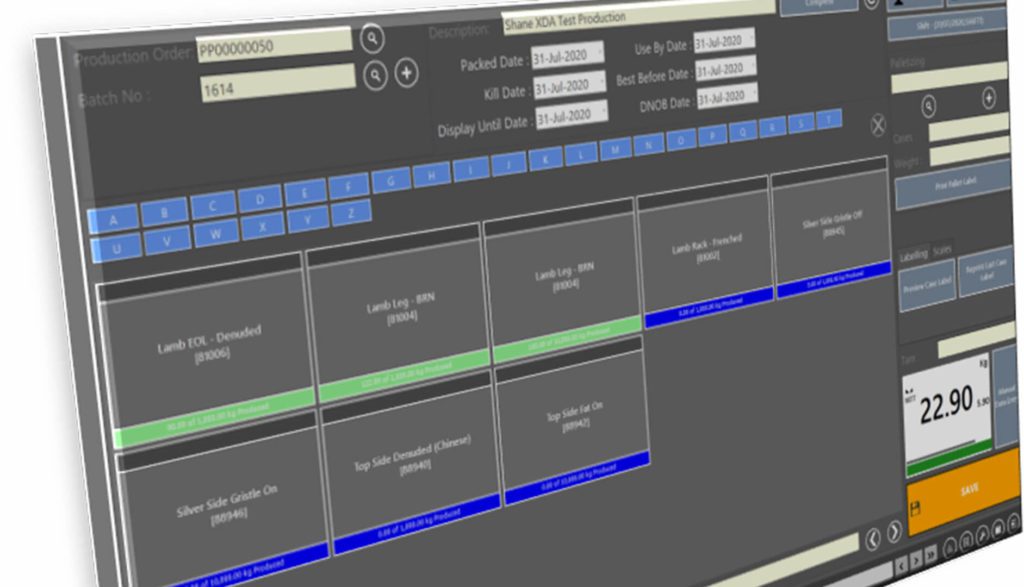

Forwards traceability allows customers to report on details of every production transaction taking place within the factory. Forward traceability grids allow users to search for purchase order (PO) number and see all the product that was received against the PO. They can then see which sales order the product was dispatched to and every step of the process in between.

Backwards traceability

Backwards traceability allows customers to report on details of every production transaction taking place within the factory. Backward traceability grids allow users to search for a Sales/Transfer order and see all the product that was dispatched against the order. They can then see which purchase order or kill lot the product was received against and every step of the process in between.

Time-Bound Traceability

Emydex traceability reporting allows for time-bound traceability, where customers know when a certain product entered a process and know how long it takes for the product to exit the process. This will then show all the transactions within the defined period.

Batch Traceability

Batches can be set up in advance of production or created on the fly on the factory floor. Product can be scanned into these batches and product produced from these batches. At times this can be a many to many relationships, however, the Emydex traceability reporting allows for customers to maintain and simply report on the traceability of product.

Designed for your industry

Our software modules

The Emydex suite of software includes a collection of independent standalone software modules designed to manage and control a particular stage of the Food Production Process e.g. Kill Line & Livestock Payments.

Each modules sits on top of the core platform, and can plug seamlessly into any other module. The full suite of modules cover all aspects of Food production from factory door-to-door.

Emydex Explained

Our software provides real-time and accurate reporting of Production, Yields, Stocks, Quality and Traceability

Our News

Industry Updates

Emydex to Showcase Cutting-Edge Solutions at IPPE 2025

Emydex Technology is excited to announce our participation in the International Production & Processing Expo (IPPE) 2025, taking place from January 28th to 30th in Atlanta, USA. Following a highly successful debut at IPPE 2024, we are thrilled to return and showcase our latest innovations in packaging, processing, and quality management.

Find Out MoreEmydex Celebrates Great Place to Work Certification

Emydex are thrilled to announce that we have become a 𝗚𝗿𝗲𝗮𝘁 𝗣𝗹𝗮𝗰𝗲 𝘁𝗼 𝗪𝗼𝗿𝗸 – Certified organisation. This certification is a testament to our commitment to creating a workplace where everyone feels valued, supported, and inspired

Find Out MoreEmydex site visit to Sustainable Beef, Nebraska

Earlier this month in Mid-November, Shane Hayes, Emydex Product Manager and Cody Musclow, Project Manager with Emydex North America, visited the new Sustainable…

Find Out MoreEmydex strengthens Team in Australasia in preparation for 2025

Five new hires join Emydex Australasia to support new customer projects next year. As a Senior Project…

Find Out MoreForresters Chicken Celebrates a Decade of Quality Management with Emydex

Over the past ten years, Forresters Chicken has leveraged Emydex’s Quality Management system to enhance accuracy, reduce human…

Find Out MoreA new Dawn for Quality systems

Dawn Meats Group, one of Europe’s leading meat processing companies, sought to streamline its factory-floor Quality Management System…

Find Out MoreSilver Fern Farms welcomes Emydex to Fourth Beef plant in Te Aroha, New Zealand

Following successful implementations of the Emydex factory floor MES system in its primary beef processing plants in Belfast,…

Find Out MoreEmydex drives Quality to New Heights at Murray’s Chicken in New York

Founded by Murray Bresky in 1992, Murray’s Chicken is dedicated to the local community and delivering top-quality meat….

Find Out More