Emydex expands in 2020 despite Covid-19 with year-on-year growth in sales

New office openings in Canada and New Zealand. New hires in Ireland, Canada, Australia, and New Zealand. New customer signings and new plant go-lives.

Sales Growth

In a year dominated by the Covid 19 pandemic, global lockdowns, as well as restrictions on domestic and international travel, 2020 has seen another period of solid performance by Emydex, at a time when all staff in all market offices are working from home since mid-March.

In the first 9 months of 2020, Emydex recorded sales growth of over 10% compared with the same 9-month period last year. Emydex is pleased to see the business continue to grow throughout what are extremely challenging trading conditions.

Remote Working

Restrictions on the international movement of people have had the biggest impact on Emydex this year, with our customers and staff restricted in their ability to visit factories for business analysis engagements and project implementations in person.

South Africa

In September, Steynsburg Pork, a new Emydex customer, went live with the first phase of their Emydex system installation, at their new greenfield plant in South Africa. This new world-class farm and abattoir facility will process up to 4,800 sows per week once operating at full capacity.

Phase 1 of the project saw Emydex go-live with a “door to door” solution, including animal delivery, pig processing kill line, carcass management, into boning, case labelling, warehouse management and sales order picking.

The project was supported on-site by Emydex’s long-standing partner for the African market, Summit Process Solutions, and a special thanks to both Rodney and Jeffrey Macer-Wright for their help and assistance on the ground during the lead up to go-live, and several weeks post-go-live during the project stabilisation phase.

New Zealand

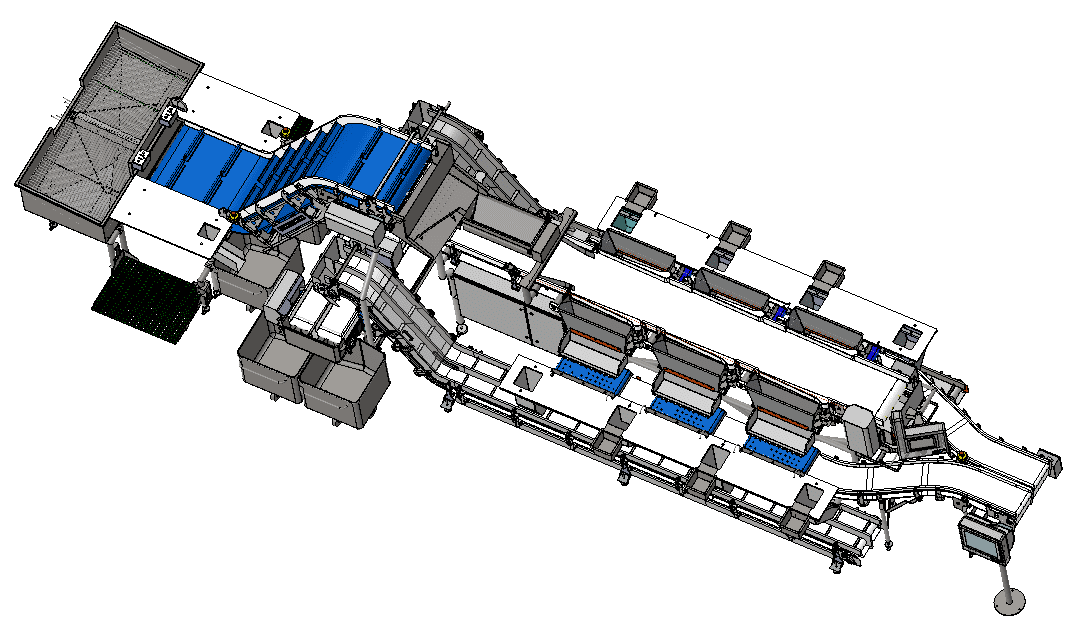

Around the same time, the Wilson Hellaby Group in North Island New Zealand went live with their first Emydex system, a state-of-the-art automated carton labelling system operating in the pack-off area of their beef and lamb boning halls of their Auckland Meat Processors (AMP) plant.

Unmanned labelling stations provide higher quality and consistency of labelling, eliminating errors, reducing reworks and recalls, whilst also reducing labour costs. Improvements in line speed and throughput mean that the automated pack labelling lines can process up to 18 cartons per minute. The system is fully integrated into the boning halls and provides real-time visibility of all stages of the production process for full traceability.

Emydex acknowledges the efforts of Ian Carson, Senior Consultant with Emydex Australia in our Brisbane office, who flew from Brisbane to Auckland and back during the lockdowns in both countries to support the Emydex go-live in the group’s Auckland Meat Processors (AMP) plant in Auckland.

Whilst onsite in AMP, Ian provided the eyes and ears for our system solutions and engineering teams working remotely on the project in our Dublin and Brisbane offices, relaying real-time video footage back to the engineers and testers working on the Emydex system solution on pre-go-live testing. Ian had to self-isolate for 2 weeks on both sides of the trip, going above and beyond the call of duty.

Canada

In Canada, the Emydex team have been working remotely with the Canadian Fishing Company (CANFISCO) to continue implementing Emydex functionality into the organisation remotely.

Having completed the first phase implementation covering Groundfish applications, the focus is now on applications for future improvements, including analysis of expected costs against actual costs, gross margin visibility at the different levels (including vessel, customer, and sales order analysis), as well as the automation of HACCP and QC processes and cold storage invoicing.

In addition, Emydex have also been completing requirements analysis for another multi-plant, major food manufacturing company in Canada. Although the first two factory requirements gathering visits were completed in person, the remaining factories have since been completed virtually using video conference technology again due to travel restrictions.

Expansion

To support growth in our two newest overseas markets, Emydex incorporated two new overseas companies in Canada and New Zealand in November and welcomed new hires to join both teams.

In Canada, Nathan Kelman joins the Emydex Canada team as a Senior Solutions Engineer. With over 8 years of programming experience working in software development roles around the Greater Toronto Area, Nathan will work on Emydex solutions development as well as support with our customers in Canada and the US

In New Zealand, Hermien Van den Berg joined the Emydex New Zealand team in September, as a Senior Project Manager, based in Auckland. With over 10 years’ experience working as a project manager for companies such as Coca-Cola in South Africa, Hermien will manage our growing New Zealand team, working remotely on customer projects including WHL and Silver Fern Farms.

(Jan 2021 update) Vadim Shegay and Wayne McRae also join the growing Emydex NZ team, both as a Senior Solutions Engineers working on ongoing Emydex projects spread over the North and South Islands in New Zealand.

Contact Sales in any of our Dublin, Brisbane, South Africa or Toronto offices