Emydex recently completed the upgrade of its Electronic Quality Management System (EQMS) to the latest Version 6 of the Emydex software suite.

A new product development project that started in 2018, working in conjunction with some of the largest food processors in Ireland and the UK who helped with system design, testing, and validation, the Electronic Quality Management System first went live with an Emydex customer, MeatCo Namibia, in late 2019.

Roll-on five years and the Quality Management System is today operating in over twenty meat, fish, and food processing plants around the world, including Emydex customers in Ireland, the UK, Canada, Namibia and South Africa.

One early-stage customer who adopted the Quality system and implemented it in their six Irish beef primal processing plants is currently extending their Emydex QMS roll-out to all their UK meat processing plants, with three UK plants live, another two currently undergoing commissioning, and a further seven to be completed by the end of 2023. In total over twenty plants will be running the Emydex quality management system, split across two country divisions.

This is very much at the core of the system i.e., the ability to centrally manage and control technical and quality data across multiple divisions, geographies, and plants, in a standard and consistent way.

At present, the system is being extended to offer capabilities for Emydex customers to perform Supplier Audits, and development is underway to offer data capture of Quality workflows, surveys, and audits, via a browser-based application running on Android devices, in addition to Windows OS devices.

Other new additions to the Quality system include product specifications & workflow planning.

Product Specifications

Product specifications functionality allows the product definition to be used for various checks based on the check being completed. For example, by completing a check on the dimensions of burgers being produced (Formax check) the workflow can be configured to compare operators’ entries against the product’s configured height, width, and weight. Similarly, if a packaging tare check is being completed, a separate workflow can compare the tare values being captured by the operator.

Workflow Planning

The workflow planning functionality was developed on the back of Emydex customer requirements to be able to manage preventative maintenance checks in more detail. This allows a super-user to schedule in more granularity based on timings and users who will complete the workflow.

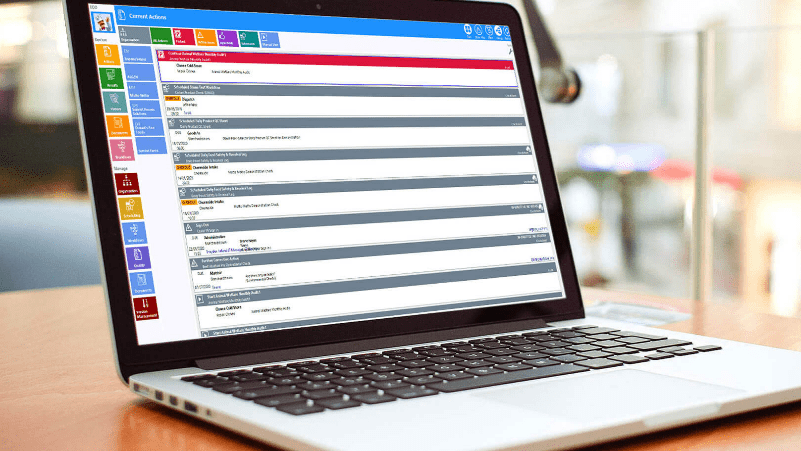

The Emydex quality management system enables Meat, Fish, and Food processors to manage their Food Safety and Quality Assurance processes. HACCP and PCP can be managed using the system which supports monitoring within the factory, such as Critical Control Points (CCP) and Good Manufacturing Practices (GMP’s). In addition, the application includes a document management system where key documents can be uploaded and version controlled, meaning that operators in the factory are always accessing the latest approved documents.

Commenting on the Quality system roll-out previously, John Coleman, Group Technical Manager with Dawn Meats said

The result is that resources have been freed up, saving cost. Less paperwork, collection is instant, no errors, less time, no printing, archive space has been freed up, we have instant and easy retrieval of documents – everything has improved and is more accurate.

We got what we wanted which is improved collection, visibility, and use of our data. That instant visibility means we have real-time situation reports. The tangible savings are obvious – less paper and less ink, for example. The less obvious savings are evident too – less time and effort, fewer mistakes and corrections, reduced hold-ups, etc. I can see if people are making the required quality checks and if they are making them at exactly the right times.

If you want to learn more – contact our Ireland, New Zealand, South Africa, or North American offices