Emydex’s dedicated Product Development team of 5 developers now work out of a separate innovation centre located in Unit 13, Northwest Centre. The team have been busy over the past 6 months working on next our generation Emydex software systems including Emydex Standard Systems, an iteration of the Emydex platform hosted in the cloud (Emydex-On-Demand) as well as many more new features including a new direct label printing (DLP) engine. The product development team are also re-engineering our core internal tool chain and libraries with the creation of a new CCL (Common Core Libraries).

Emydex Standard Systems

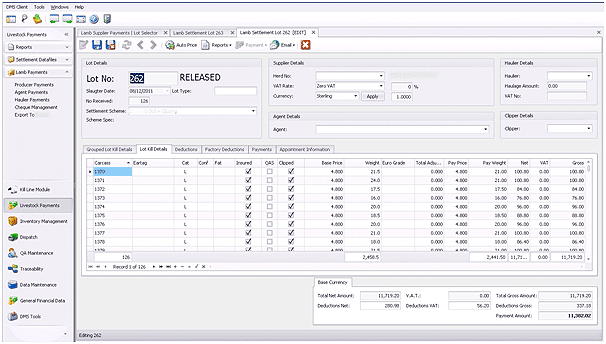

As the Emydex platform has matured over the past 10 years, we have seen commonalities emerge in the features our customer’s request. Overtime, functionality has begun to gravitate towards a standardised set of rules and methodologies. In tandem we have asked by some food processors to provide Emydex systems with less reliance on customisation in favour of ease and speed of installation, deployment, usage and management.

Typically smaller to medium sizes food processors have enquired after such standardised systems. The Emydex Standard Systems (ESS) project takes all the Emydex experience and know-how gained in designing and deploying production management systems for our customers over the past 10 years, to produce our standard versions of each essential component within in a typical end-to-end food production process from Intake, through Into-Production, Packing, Labelling, Order Picking and Dispatch

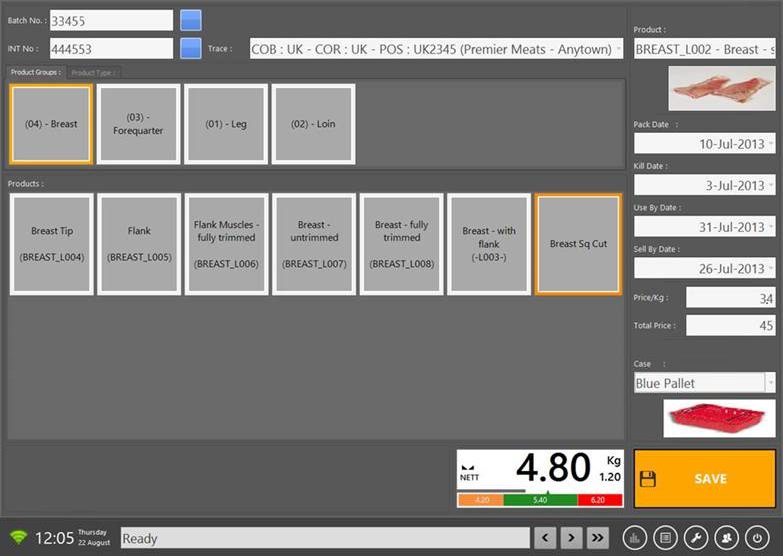

Standard Intake: The goal of this project phase is to standardise the process of goods-in and quality control. We will take a number of different features from existing systems and blend them together to provide a standardised Intake module. This new module will be released on our MDA software (that can operate on Industrial PC terminals) and is broken down into the following deliverables:

- Initial Intake

- QC Hold and Intake Returns

- QC Release

- Post Intake / Raw Goods In

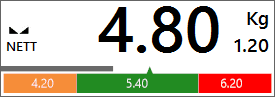

You may also notice we have done a lot of work around our new embedded scales indicator, including re-skinning and adding further validation functionality around limits and checks. This indicator is just one of the new standardised components being built in tandem with standard packing:

Standard Warehousing: This project phase will see a re-write of our standard dispatch warehousing system (SDA) that typically runs on hand-held scanning terminals such as the Motorola Symbol MC9090 range. Some key deliverables of the SDA standardisation project will include:

- Swapping out Windows CE database running on handhelds for SQL Lite eliminating the requirement to install IIS on local servers and to sync via IIS services. SQL lite is also a higher performing database than SQL CE.

- Customising the SDA application to work with Emydex-on-demand i.e., delivery via the cloud, licencing and subscription services for value-added/overseas resellers

- Reworking of SDA application to work more seamlessly with higher resolution screen-sizes eg., MC9190

- Creating a version of the new CCL to work with the compact framework

- Standardisation of SDA forms such as:

- QC Release

- Into Production

- Return From Production

- To Rework

- Palletizing

- Movements

- Stock Reconciliation/Cycle

- Order Picking

- Shipments

- Customer Returns

The Emydex Standard Systems project takes the best of each of our systems and applies a common standard across the whole suite of products. Configuration will be provided; that will allow each customer to configure their system to meet their own needs without the need for Business Logic or custom code written by Emydex. While configuration is not as extensible as customisation, we feel it will provide ample personalisation for smaller food processors who do not have m/any internal IT staff.

Emydex On-Demand

Emydex on Demand is an iteration of Emydex delivered via and powered by the cloud (Microsoft Windows Azure). Emydex on Demand will enable Emydex to deploy systems to our customers in a fraction of the time, to maintain and upgrade systems quicker and easier, and allow customers more freedom than any comparable system on the market in terms of installation availability.

Many distributors working within our specialised food processing industries, both here and overseas, have expressed a desire to have the ability to install and manage Emydex systems for their customers. Traditionally the level of customisation desired by customers meant that only Emydex and it’s team could reasonably manage a customers requests. With Emydex on Demand and its configuration model, we will be able to provide a partner system with industry champions who wish to offer Emydex as a solution to their customers. Both Emydex and it’s partners will be able to support customers ranging from small all the way to enterprise level and provide standardised solutions with custom configuration on a per customer basis.

Direct Label printing

Traditionally label printing has presented a bottleneck for fast paced production. Because of the complexity of label design and templating, printing is usually provided via Windows Spooler or via supporting functionality from a given Label Designer company, both of which are slow. Our innovation team has designed a new direct label printing engine that allows customers to design labels in a third party label designer (we currently support NiceLabel) and import them into their Emydex system. By importing the label in to Emydex we can then optimise and print the label directly over TCP or Serial resulting in noticeably quicker print times. The direct label printing engine will be available for our Client, PCA, and MDA for all customers. Emydex will continue to support and maintain Nice Labels in tandem which will better suit our customers that require more WISIWIG type functionality, but for those in the need of high-speed label printing (such as retail production lines) the DLP engine will be the better option.

Common Core Libraries

At Emydex we have an extensive collection of internal tooling and support libraries which enable us to build great software. The Common Core Libraries or CCL for short is a reworking of these libraries and tools that includes automated testing, improved documentation and modernisation. While the CCL is an internal project for the most part, the improvements it brings will be noticeable from a customer’s perspective. Some of the deliverables of interest to our customers include:

- A completely new and powerful logging system which will provide testers and support with detailed and relevant information for the purposes of troubleshooting or diagnostics. With this new system we are able to identify slowdowns and bottlenecks in our software down to 1/3rd of a millisecond.

- A modern and robust threading model. Threading is complicated but it allows software to be much more responsive by allowing tasks to run in the background without impacting the front end. We have built a new threading model that is much easier to implement and manage from a developers perspective. This will allow our developers to run more work as background tasks, which in turn will improve the responsiveness of our system.

- We now use the CCL as a test bed for a specific type of testing (Unit testing). Unit tests are extremely small, automated tests. These tests break code down into logical units and test if the unit behaves as expected. What makes unit tests so useful is the fact that thousands of tests can be ran at the click of a button with no interaction from a developer.

Emydex Standard Systems, Emydex-on-Demand, Direct Label Printing and other products and enhancements like CCL represent Emydex’s continuing drive to evolve to meet the needs of customers now and in the future.

By investing heavily in our existing products and innovating based on customers’ needs we feel we are in the best position possible to provide systems that work to optimise and support your business.