Utilise Analytics to derive Insights into your production data

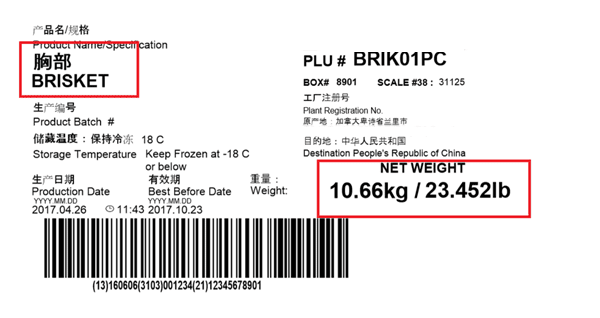

Data & Information has been referred to as the oil of the 21st century. Having the right data, at the right time, is vital to the success of any food processor.

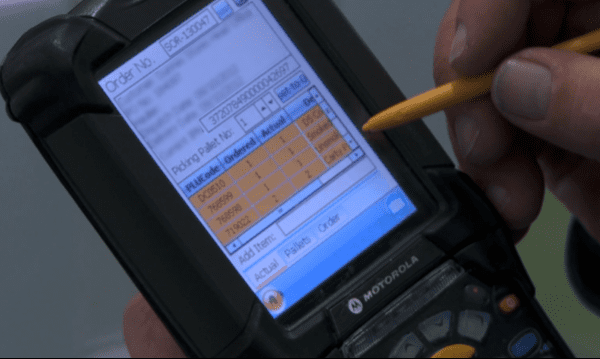

The first step in this process is ensuring data is collected accurately, in a consistent method. Once captured, this data should be easily accessible and understandable by various stakeholders in the business.

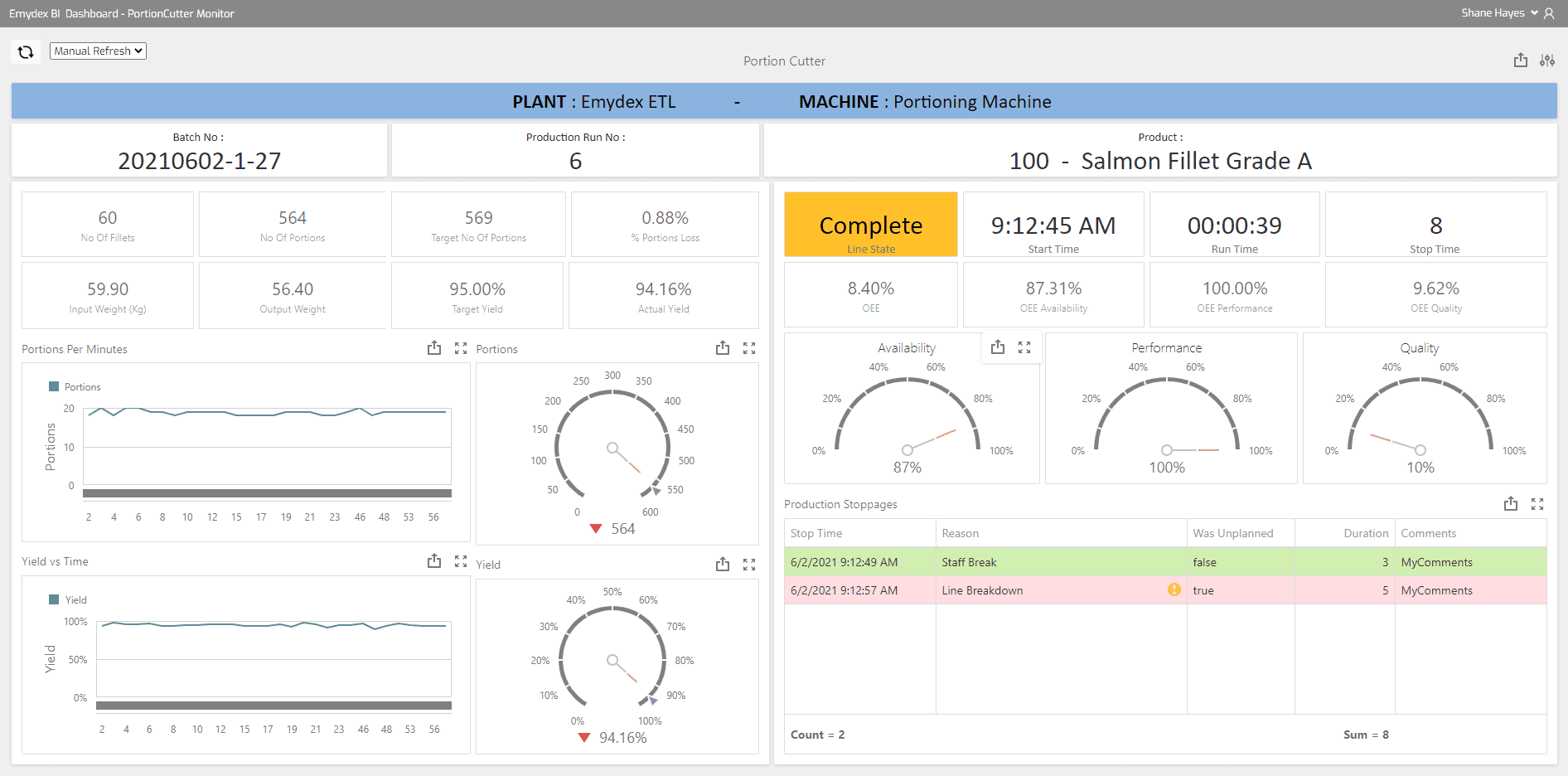

Analysing data will tell stories and show insights that would otherwise go unnoticed. Analytics enables people to see the wood from the trees, to see patterns and trends in large datasets, that can assist with identifying issues within production environments, identify trends within factories, benchmarking business units, reporting KPI’s and can teach you things about your business you didn’t know before – replacing guesswork and gut feel.

How Emydex will help you strike oil

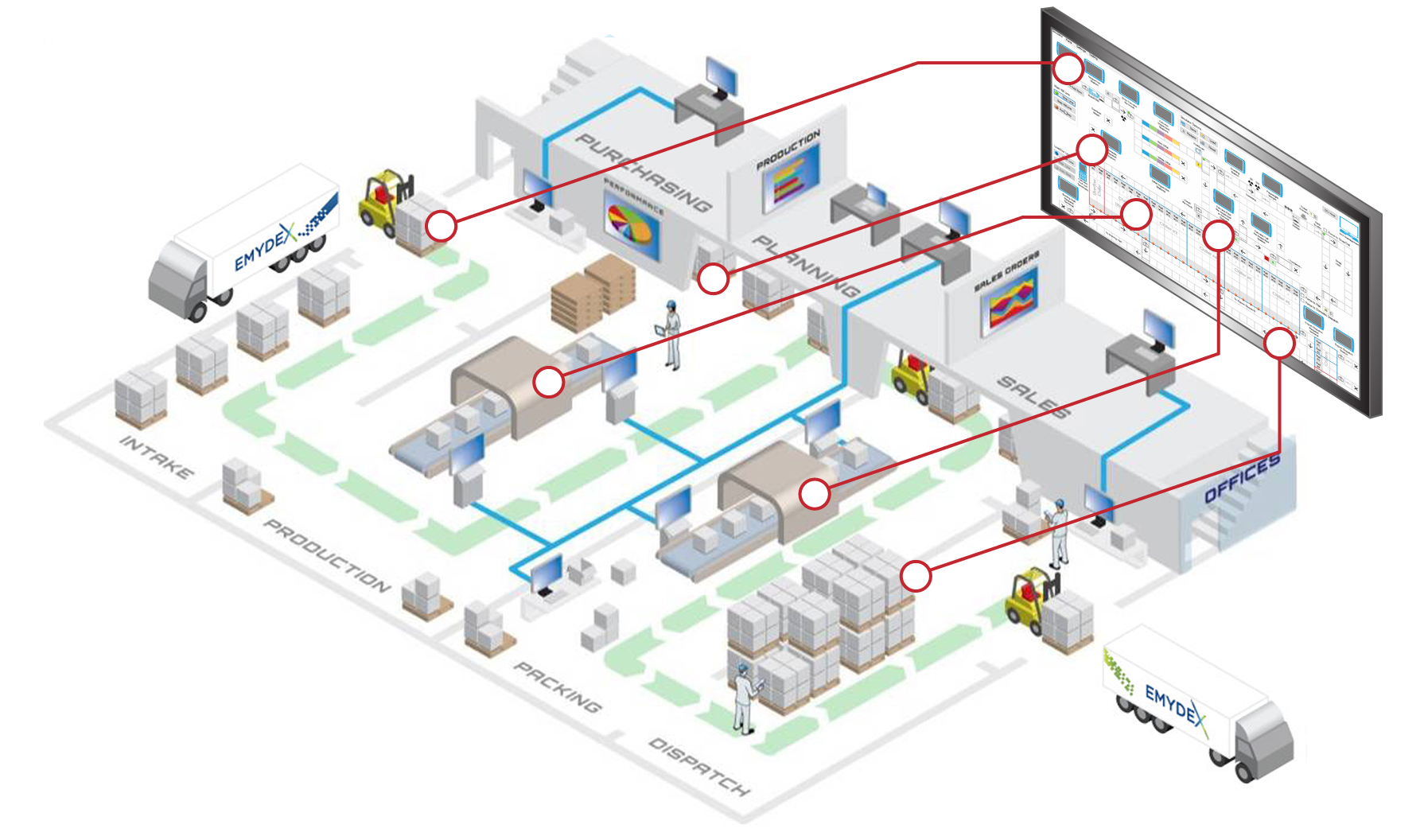

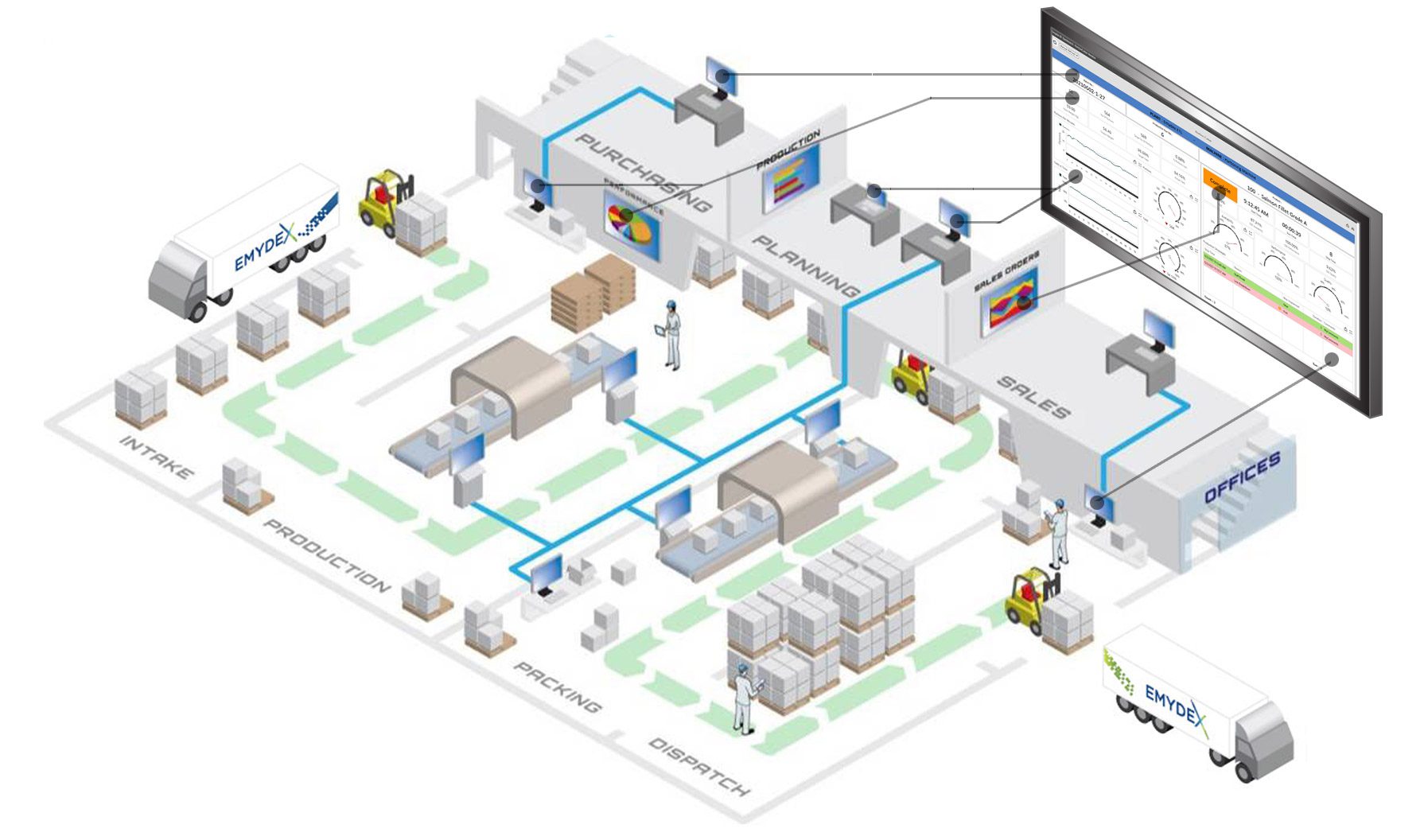

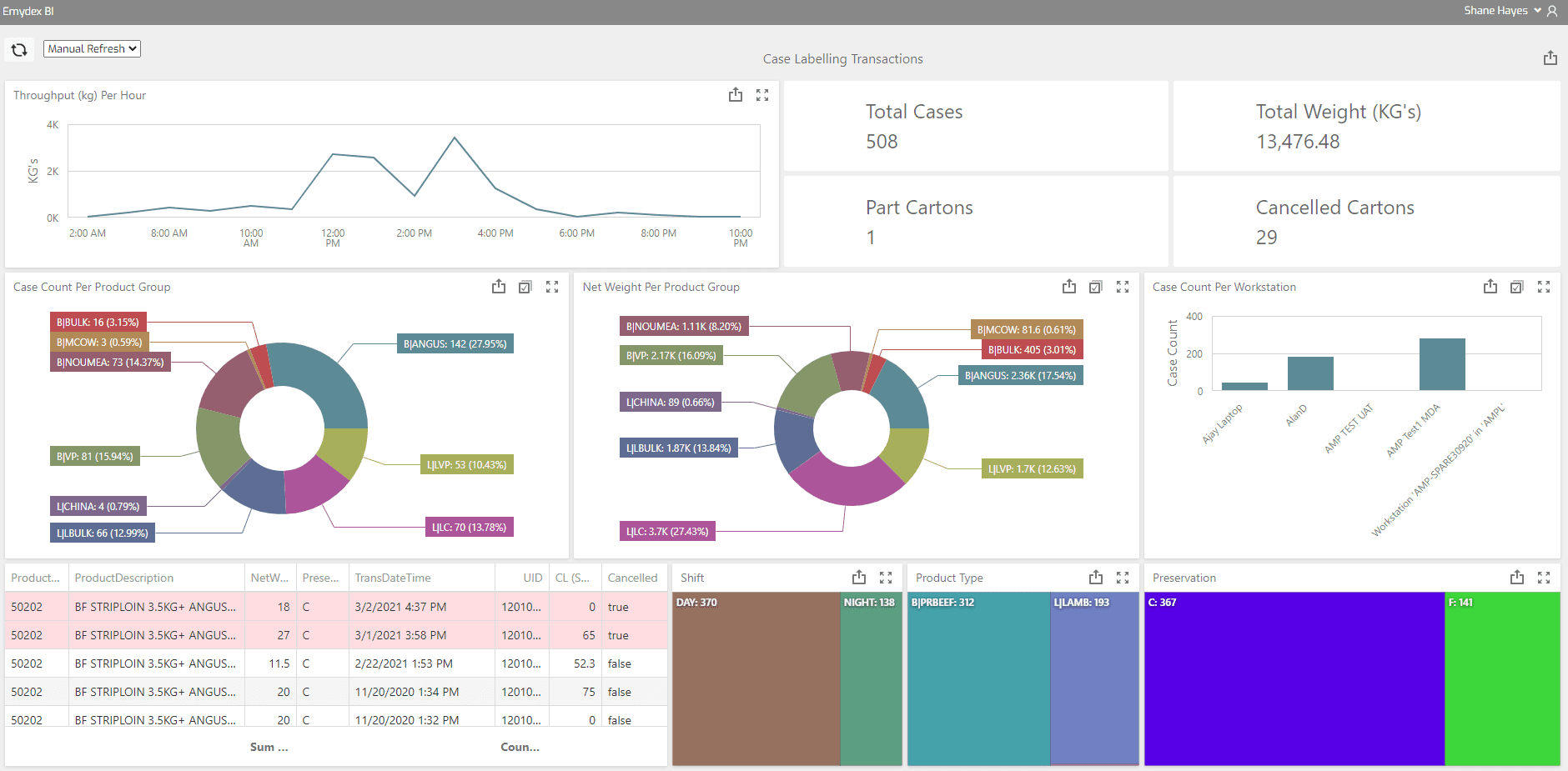

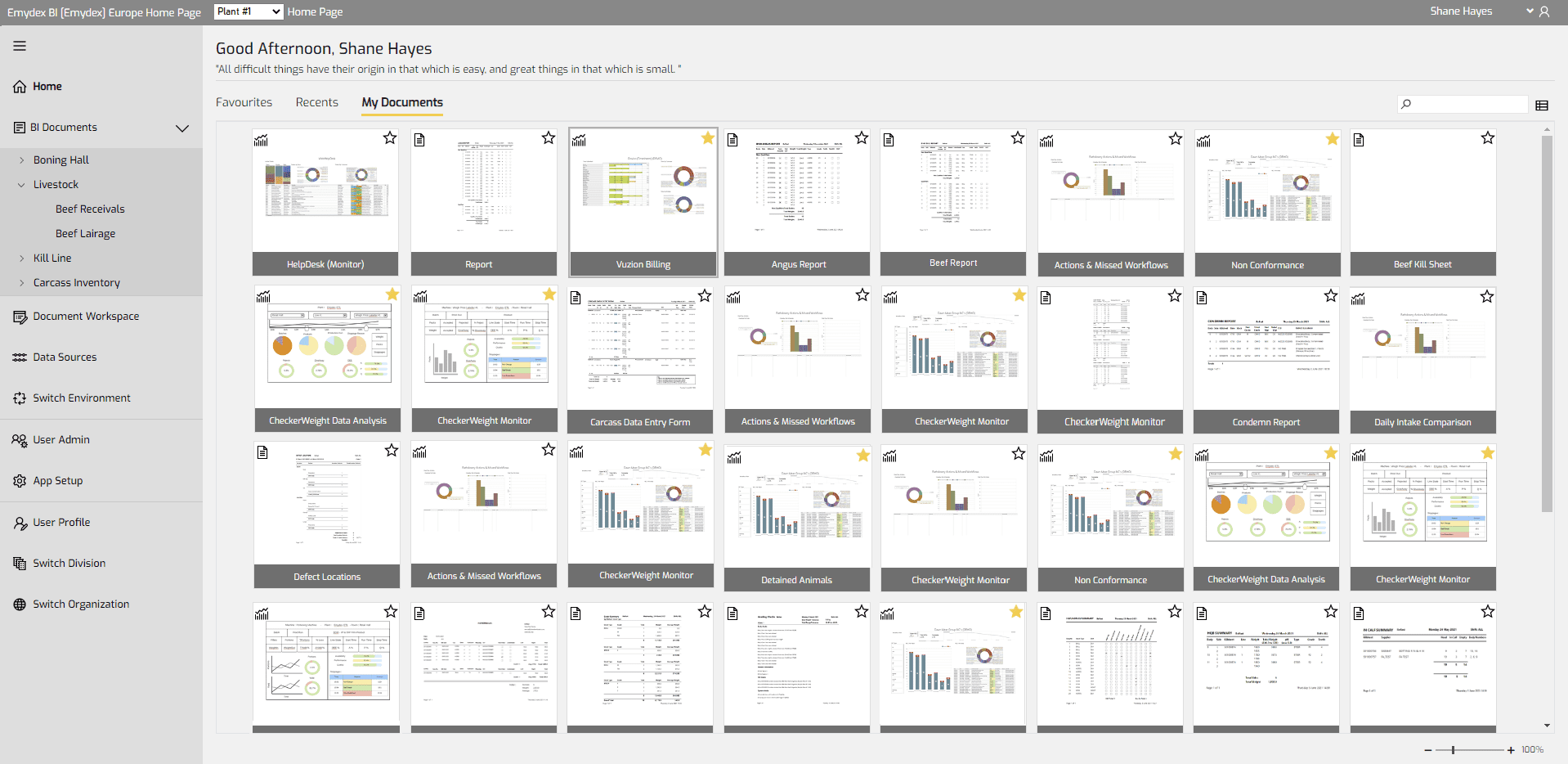

Emydex’s latest software module, Emydex BI, provides Emydex customers with a slick new interface that allows users to easily access and visualise data from any software system including Emydex factory floor Production systems, Emydex’s Quality Management system, 3rd party ERP systems, other shop floor Manufacturing Execution Systems (MES’s) as well as various other third-party systems.

Cross Platform App

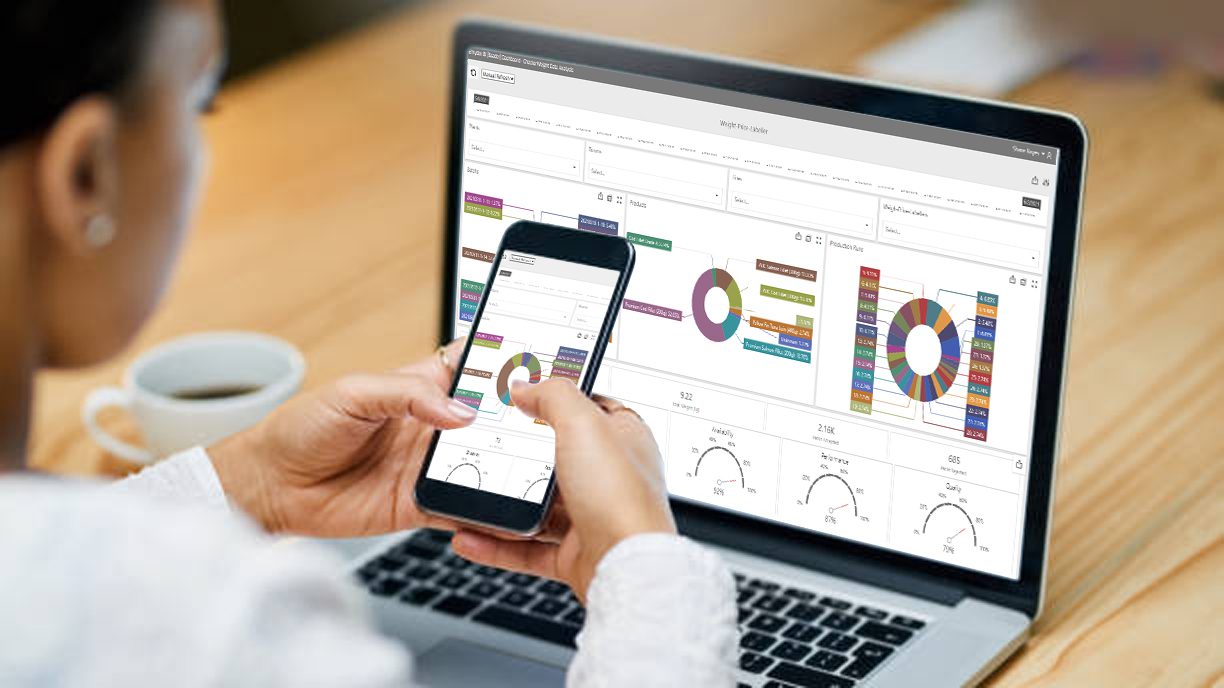

The Emydex BI app, which is available as both a web app running in a browser or Windows desktop app, provides rich data visualisation for end-users allowing them to drill into, slice and dice and filter various data using sixteen different interactive presentation widgets. Connecting to multiple systems, Emydex BI pulls data from multiple sources into one location, where users can find all the answers they are looking for (as well as questions they didn’t have!)

Sitting at the enterprise level of the Emydex architecture, the Emydex BI tool is easily able to connect to multiple plants systems to access the data depending on the level of security configured per user.

Share & Refresh

Share the results easily with the ability to export the entire dashboard results, or an individual widget at the press of a button.

Individual dashboards can be set up with automatic refresh rates, meaning your data is always up to date!

Design With Ease

Administrator users can easily design and update dashboards using either the web or desktop dashboard editor with tools to bring your data to life.

The Emydex BI App has version control built in, allowing you to update and publish documents with confidence.

The Emydex BI tool also supports static reports, meaning you are able to produce your static formatted reports directly from the Emydex BI tool!

Features

- Cloud-Based or Windows Desktop

- Easy to use widgets to visualise data

- Easily filter/drill down/interrogate data

- Combine multiple data sources/views into one dashboard

- Mobile/Tablet access using the web app

- Configurable automatic update refresh rates

Benefits

- Reduce reporting time

- Increase business awareness

- Real-time access to data

- Data on the move using mobiles/tablets with the Webapp

If you want to learn more – contact Ireland, Australia, South Africa or North America offices