A fish processing unit capturing accurate yield data

Nolan’s Quality Seafoods was established in 1912 by Harry Joseph Nolan. He worked as a part-time fish salesman in the Belfast Fish Market when he decided to use his knowledge and experience to set up on his own.

That choice led to the growth of a business that covers three generations, having passed to Vincent Nolan and then to his son in turn George Nolan, their present chairman. Today, Harry Joseph Nolan’s idea has resulted in a successful family business which employs almost 300 people in Ireland and Scotland with a turnover of over €30 million.

Their expertise and time honoured tradition can be experienced whenever one tastes their Smoked Salmon products. As Master Smokers they produce Conventional Smoked Salmon, Organic Smoked Salmon, as well as Wild Smoked Salmon in a wide range of pack sizes and formats.

They also produce: Gravad Lax, Smoked Mackerel, SmokedKippers, Smoked Haddock, Smoked Cod, High quality Prawn Cocktails and Added value Poached Salmon products.

As fresh fish merchants, they offer Cod, Hake, Plaice, Whiting, Haddock and Mackerel, as well as a large range of fresh and frozen shellfish, prawns, crab meat and lobster.

Nolan’s Dublin processing unit and Smokers are located less than 800 metres from the River Liffey, through which Salmon and Trout swim on their migratory routes to their traditional spawning grounds.

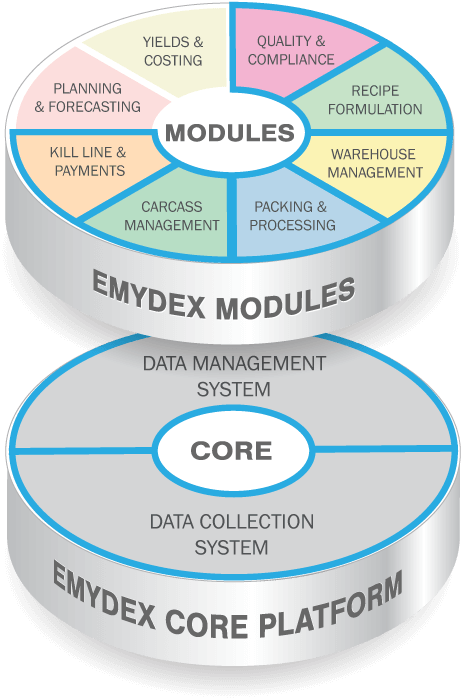

Here, Emydex helps Nolan’s Quality Seafoods to capture accurate yield data; weight-on versus weight-off, as well as production throughput; time-on versus time-off, from each of the company’s filleters in real-time. This information is stored in a central cloud-hosted Emydex database, which can be viewed by both operators on the line, as well as production supervisors on an industrial monitor running Emydex in the factory.

What Nolan's Say

“The ability to export accurate information instantly from the Emydex system has greatly improved the process by which the filleters are paid. Before, the production supervisor would have to manually calculate each filleter’s weights and rate of pay. This information is now exported and sent directly to our accounts department.“

Sean Carolan, IT Manager, Nolan's Quality Seafoods

Challenge

- Major Irish / Scottish Salmon & Seafood processor

- Integrate to SF Engineering automated filleting system

- Real time reporting required on:

-Yields

-Traceability

-Operator Performance

Solution

Outcome

- Production Traceability

- Automated distribution of products

- Increased efficiency

- Increased throughput

- Real-time Production reporting on:

-Individual & Group Yields

-Supplier Comparisons

-Throughput

-KPI Monitoring

Our News

Industry Updates

New FDA Requirements for Seafood Traceability

New FDA Requirements for Seafood Traceability Seafood Traceability Requirements Retailers, restaurants, and consumers have been very frustrated…

Find Out MoreSuccess in a Greenshell

Success In A Greenshell Whakatōhea is an indigenous New Zealand iwi (confederation of Māori tribes) centred around the…

Find Out MoreWhen Canfisco went fishing for an IT partner

Meet the client The Canadian Fishing Company (Canfisco) has sustainably harvested wild fish from the coastal waters of…

Find Out MoreEmydex Traceability in Tuna Processor in Philippines

Blueyou leads and participates in Fishery Improvement Projects, one of which projects was to implement an Emydex electronic…

Find Out MoreHJ Nolan Salmon Filleting Yield Control System

HJ Nolan Ltd have been in business for 95 years, since 1912. The company sells premium seafood products…

Find Out MoreClogherhead Fishermen’s Co-Op: Labelling at Sea

Clogherhead Fisherman’s Co-Op, is a leading Irish Seafood producer based in Clogherhead, Co. Louth, on the East Coast…

Find Out More