The largest independent cold store in Northern Ireland

Interfrigo is the largest independent cold store in Northern Ireland, operating a 136,000 sq ft state-of-the-art cold store with storage capacity for 20,000 pallets.

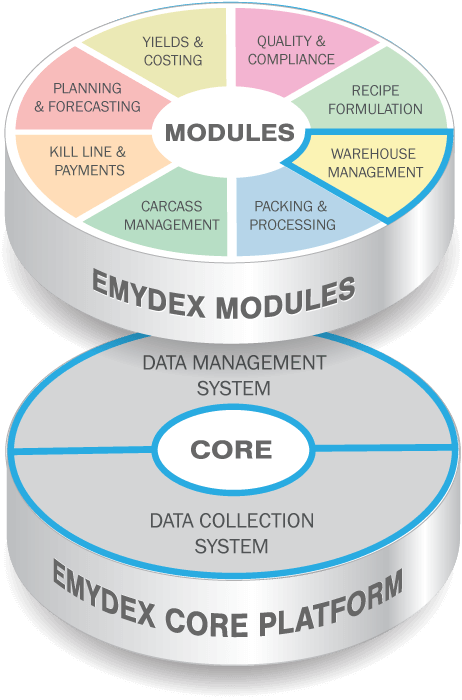

Interfrigo provides third party cold storage for a number of local and international food producers, including many of Emydex’s food processing customers. With Emydex’s ‘Intersite-transfers’ feature, Interfrigo customers also running Emydex are able to dispatch and trace shipments into and out of the Interfrigo Cold Store seamlessly.

Once goods are received into Interfrigo, they are verified, put-away, picked and dispatched all via Emydex, with the ability to break-down and rebuild pallets to fulfill sales orders as required. Emydex software is also running on truck-mounted terminals in all Interfrigo’s fork-lifts.

Following on from the original implementation, Legislative and Customer driven demands have been introduced requiring the management and reporting of food allergens contained within any food products stored in the Cold Storage facilities. Emydex have further extended their warehousing system to capture and report on the details of any specific allergens contained within every product stored on behalf of Interfrigo customers.

What Interfrigo Says

“As we manage stock on behalf of some large Food Processing companies who also operate Emydex’s Production Management systems in their factories, it made sense for Interfrigo to replace our existing legacy WMS with Emydex’s Warehouse Management system... It provides us with real-time links to our customers who use Emydex. The benefit of this is the ability to manage stock transfers and sales order picking requests instantly.”

Brendan McAlonan, Operations Manager, Interfrigo

Challenge

- Restrictive WMS in place

- Little flexibility to make changes

- Little flexibility to add reports

- Manual Traceability reporting

- No box level traceability

- Manual stock control and stock reconciliation processes

- Requirement to integrate customers

Solution

Outcome

- Full Stock Management, Intake, Put-away, Sales Order Picking & Dispatch control

- Full box-level Traceability

- E-Transfer integration to Dunbia, Ballymena and Moy Park, Ballymena

- Invoicing & Fork lift terminals

- Flat file integration to other customers

- Flexible reporting & system changes

- Allergen control reporting

Our News

Industry Updates

A new Dawn for Quality systems

Dawn Meats Group, one of Europe’s leading meat processing companies, sought to streamline its factory-floor Quality Management System…

Find Out MoreSilver Fern Farms welcomes Emydex to Fourth Beef plant in Te Aroha, New Zealand

Silver Fern Farms Expands Emydex Integration in Te Aroha The Silver Fern Farms Emydex implementation continued following successful…

Find Out MoreEliminate costly carton rejections with Emydex and Meat Messaging

The international trade of food products has over time become highly competitive with many large multinational companies emerging…

Find Out MoreKill Line Live in Central Agri Group, Victoria, Australia

In 2016 Central Agri Group, formerly Central Meat Exports, re-opened their newly refurbished beef plant in Trafalgar as…

Find Out MoreBeef Processing Software Live in MeatCo Namibia

WINDHOEK – NAMIBIA: The Emydex implementation team returned to Ireland after the latest phase of Emydex system deployments…

Find Out MoreTraceability System Live in La Rousse Foods

DUBLIN/BELFAST – IRELAND: With operations located in Dublin and Belfast, La Rousse Foods specialise in the supply of…

Find Out More